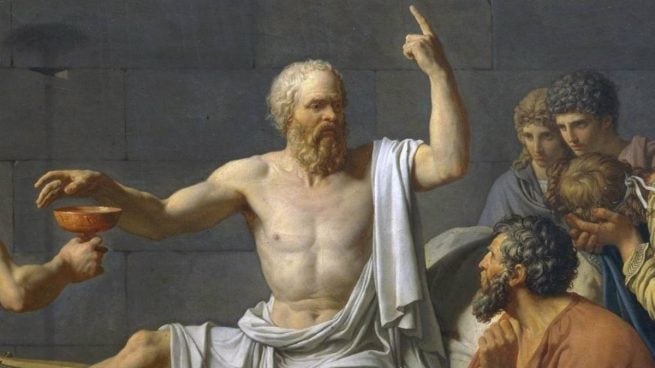

You can see from Figure 1-1 that Lean thinking involves a certain amount of

jargon – some of it Japanese. This section defines the various terms to help you get Lean thinking as soon as possible:

✓ Heijunka provides the foundation. It encompasses the idea of smoothing processing and production by considering levelling, sequencing and standardising:

• Levelling involves smoothing the volume of production in order to reduce variation, that is, the ups and downs and peaks and troughs that can make planning difficult. Amongst other things, levelling seeks to prevent ‘end-of-period’ peaks, where production is initially slow at the beginning of the month, but then quickens in the

last days of a sale or accounting period, for example.

• Sequencing may well involve mixing the types of work processed.

So, for example, when setting up new loans in a bank, the type of loan being processed is mixed to better match customer demand, and help ensure applications are actioned in date order. So often, people are driven by internal efficiency targets, whereby they process the ‘simple tasks’ first to get them out of the way and ‘hit their

numbers’, leaving the more difficult cases to be processed later on.

This means tasks are not processed in date order, and people are

reluctant to get down and tackle a pile of difficult cases at the end

of the week, making things even worse for the customer and the

business.

• Standardising is the third strand of Heijunka. It seeks to reduce

variation in the way the work is carried out, highlighting the

importance of ‘standard work’, of following a standard process

and procedure. It links well to the concept of process manage-

ment, where the process owner continuously seeks to find and

consistently deploy best practice. Remember, however, that you

need to standardise your processes before you can improve them.

Once they’re standardised, you can work on stabilising them, and

now that you fully understand how the processes work, you can

improve them, creating a ‘one best way’ of doing them.

In the spirit of continuous improvement, of course, the ‘one best

way’ of carrying out the process will keep changing, as the people

in the process identify better ways of doing the work. You need to

ensure the new ‘one best way’ is implemented and fully deployed.

✓ Jidoka concerns prevention; it links closely with techniques such as

failure mode effects analysis (FMEA), which are covered in Chapter 10.

Jidoka has two main elements, and both seek to prevent work continu-

ing when something goes wrong:

• Autonomation allows machines to operate autonomously, by shut-

ting down if something goes wrong. This concept is also known as

automation with human intelligence. The ‘no’ in autonomation is

often underlined to highlight the fact that no defects are allowed to

pass to a follow-on process. An early example is from 1902, when

Sakichi Toyoda, the founder of the Toyota group, invented an

automated loom that stopped whenever a thread broke. A simple

example today is a printer stopping processing copy when the ink

runs out.

Without this concept, automation has the potential to allow a large

number of defects to be created very quickly, especially if process-

ing is in batches (see ‘Single piece flow’, below).

• Stop at every abnormality is the second element of Jidoka. The

employee can stop an automated or manual line if he spots an

error. At Toyota, every employee is empowered to ‘stop the line’,

perhaps following the identification of a special cause on a control

chart (see Chapter 7).

Forcing everything to stop and immediately focus on a problem

can seem painful at first, but doing so is an effective way to quickly

get at the root cause of issues. Again, this can be especially impor-

tant if you’re processing in batches.

✓ Just in Time (JIT) provides the other pillar of the TPS house. JIT

involves providing the customer with what’s needed, at the right time, in

the right location and in the right quantity. The concept applies to both

internal and external customers. JIT comprises three main elements:

• Single piece flow means each person performs an operation and

makes a quick quality check before moving their output to the

next person in the following process. Naturally this concept also

applies to automated operations where inline checks can be car-

ried out. If a defect is detected, Jidoka is enacted: the process is

stopped, and immediate action is taken to correct the situation,

taking countermeasures to prevent reoccurrence. This concept is

a real change of thinking that moves us away from processing in

batches.

Traditionally, large batches of individual cases are processed at

each step and are passed along the process only after an entire

batch has been completed. The delays are increased when the

batches travel around the organisation, both in terms of the trans-

port time, and the time they sit waiting in the internal mail system.

At any given time, most of the cases in a batch are sitting idle, wait-

ing to be processed. In manufacturing, this is seen as costly excess

inventory. What’s more, errors can neither be picked up nor

addressed quickly; if they occur, they often occur in volume. And,

of course, this also delays identifying the root cause. With single

piece flow, we can get to the root cause analysis faster, which

helps prevent a common error recurring throughout the process.

• Pull production is the second element of JIT. Each process takes

what it needs from the preceding process only when it needs it and

in the exact quantity. The customer pulls the supply and helps avoid

being swamped by items that aren’t needed at a particular time.

Pull production reduces the need for potentially costly storage

space. All too often, overproduction in one process, perhaps to

meet local efficiency targets, results in problems downstream.

This increases work in progress, and creates bottlenecks.

Overproduction is one of the ‘seven wastes’ identified by Ohno

and covered in Chapter 9.

• Takt time is the third element of JIT, providing an important addi-

tional measure. It tells you how quickly to action things, given the

volume of customer demand. Takt is German for a precise interval

of time, such as a musical meter. It serves as the rhythm or beat of

the process – the frequency at which a product or service must be

completed in order to meet customer needs. Takt time is a bit like

the beat of the drum on the old Roman galleys for synchronising

the rowers.